Tanks & Boxes

NTE’s tanks and boxes can be utilized as temporary storage for a variety of industrial and commercial applications, including:

- Construction Runoff

- Cooling Tower Cleaning

- Wastewater Storage & Treatment

- Environmental Remediation

- Hydrotesting & Pipeline Integrity Testing

- Tank Cleaning

- Turnaround Temporary Storage

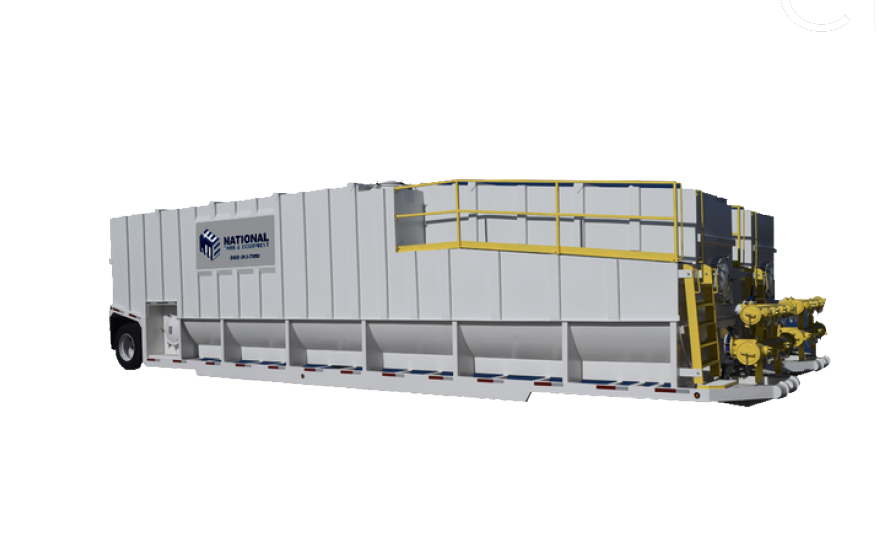

Closed-Top Tanks

Styles Available:

- Vapor Tight Smooth Wall, Round Bottom, Steam Coil, Acid Frac, Mini Frac (200BBL/8400 Gallon)

- Standard 500 BBL/21,000 Gallon Capacity

- 500 BBL / 21,000 Gallon Capacity

- 42′ L x 102″ W x 133″ H

- Stairs with Fixed Rail

- Single & Double Manifold Options

- 500 BBL/21,000 Gallon Capacity

- 42’ L x 102” W x 133” H

- 22” W Stairway

- Single & Double Manifold Options

- 8,500 Gallon Capacity

- 23 1/2″ L x 102″ W x 105″ H

- Skid Mounted for easy transport on roll-off truck

Specialty Tanks

Vertical Frac Tanks

The advantages of vertical frac tanks are numerous. Their smaller footprint allows for maximum fluid storage in tight spaces.

They are easily transportable, eliminating costly and time-intensive load permits.

- Optimizes Storage in a Smaller Footprint

- Steam Coil Options Available

- Standard 350 BBL/ 14,700 Gallon Capacity

Mix Tanks

-

Steam Coil Options Available

-

Standard 500 BBL/21,000 Gallon Capacity

-

Vertical Mix Tanks Offer 350BBL/14,700 Gallon Capacity

Stainless-Steel Tanks

- Hazardous & Non-Hazardous Fluid Storage

- Containment WhenTemperature & Fluid pH are Factors

- Standard 500 BBL/21,000Gallon Capacity

-

Portable with SteelCage Protection

-

Caustic or Acidic Fluid Containment

-

150 BBL/6300 (Single),300 BBL/12,600(Double) GallonCapacities

Stainless-Steel Tanker Trailers

-

Industrial Storage/Waste Transport Applications

-

316 Stainless Steel Construction

-

Liquid Level Gauge

-

2” Vapor Recovery Line

-

Standard 167 BBL/7,000 Gallon Capacity

Double-Walled Tank

For Specialty Fluid Storage Applications

- Built-In Secondary Containment for Environmental Protection

- Standard 450 BBL/ 18,900 Gallon Capacity

Open-Top Tanks

Styles Available:

-

Weir Tanks, Gas Busters, Mud Tanks

-

250, 400, 500 BBL/ 10,500, 16,800, 21,000 Gallon Capacities

Acid Tanks

- 500BBL Capacity

- Available in Skid or Mobile Configuration

- Skid = 32′ L x 10’6″ D

- Mobile = 45′ L x 102″ W x 117″ H

- 200 BBL Capacity

- 45′ L x 102″ W x 133″ H

- Double Barrel

- Construction & DebrisRemoval Applications

- Non-Watertight Fluids &Solids Containment

- 20, 25, 30, 40 Yard Capacities Available

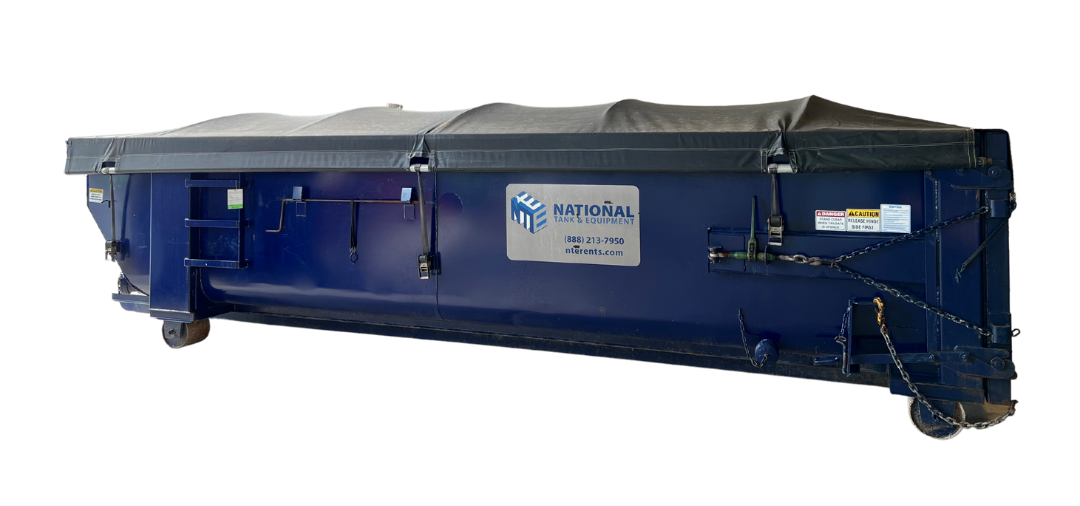

- Ideal for Sludge & Solids

- Movement in Hydro-Excavation, Manufacturing, and Paper Mills Applications

- Watertight Fluids & SolidsContainment

- Standard 25-Yard Capacity

- SeparatingApplications

- Watertight Fluid & Solids Containment

- Standard 25 YardCapacity

- Open & Closed Options Available

-

Industrial Storage/Waste Transport Applications

-

316 Stainless Steel Construction

-

Liquid Level Gauge

-

2” Vapor Recovery Line

-

Standard 167 BBL/7,000 Gallon Capacity